Biodiesel

Biodiesel

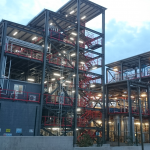

TECHNOILOGY has developed a very efficient biodiesel plant, capable of processing all kinds of oils and fats, including fried oil and other low grade raw materials.

Transesterification:

• Continuous trans-esterification process

• High efficiency thanks to special reactors

• Low methanol and catalyst consumption

• High quality biodiesel with low T.C.M and monoglyceride

• High conversion rate

• Zero effluent

• Plant coupled with distillation unit when a special final product is required

• High grade of crude glycerine as by product

Methylester Distillation

TECHNOILOGY can provide Biodiesel Distillation unit for customers having Biodiesel Production plants that can’t meet the standards requested by the actual market and in particular T.C.M, monoglyceride value, sulphur value and cold soak filterability.

Also FAME Fractional Distillation Columns can be provided in order to obtain a pure cut like C12 – C14 – C16 – C18 with purity up to 99%.

Glycerine from methylester

TECHNOILOGY has developed a special in-house process where crude Glycerine can be treated by a Purification – Concentration – Distillation process in order to obtain high Pharma Glycerine quality.

Glycerolysis

TECHNOILOGY can also provide processes for the conversion of high FFA Oils and Fats (such as POME, PFAD – ACID OIL) into added value products to be used in Biodiesel Production.

Esterification

TECHNOILOGY can also provide processes for the conversion of high FFA Oils and Fats (PFAD – ACID OIL) into added value products to be used in Biodiesel Production.