A glycerine refinery is a facility that processes raw glycerol, a byproduct of various industries like biodiesel production, soap manufacturing, and fatty acid production. Glycerol, commonly known as glycerine or glycerin, is a colorless, odorless, and viscous liquid with various applications in pharmaceuticals, food and beverage, personal care products, and more.

The primary purpose of a glycerine refinery is to purify and refine crude glycerol obtained from different sources to produce high-quality, commercial-grade glycerine. The refining process involves several steps to remove impurities and contaminants, resulting in a refined glycerine product that meets industry standards and customer specifications.

Here are the typical steps involved in glycerine refining:

- Pre-treatment: Crude glycerol obtained from various sources may contain water, salts, methanol, fatty acids, soap, and other impurities. The pre-treatment step involves removing water and methanol, often through distillation or other separation techniques.

- Neutralization: In this step, any free fatty acids present in the crude glycerol are neutralized using an alkaline solution. This helps in reducing acidity and improving the quality of glycerine.

- De-colorization: Crude glycerol often has a yellowish or brownish color due to the presence of impurities. De-colorization involves using activated carbon or other adsorbents to remove color-causing substances and make the glycerine colorless.

- Deodorization: Some impurities in crude glycerol can lead to undesirable odors. Deodorization involves heating the glycerine under vacuum conditions to remove volatile compounds responsible for odors.

- Distillation and Purification: Distillation is used to separate different components and further purify glycerine. The refining process may involve multiple distillation steps to achieve the desired level of purity.

- Filtration: Filtration is often employed to remove any remaining solid particles or impurities that may have been missed in earlier stages.

- Quality Control: Throughout the refining process, rigorous quality control measures are implemented to ensure that the glycerine meets the required industry standards and product specifications.

- Storage and Packaging: After the glycerine has been refined and passes quality checks, it is stored in suitable containers and then packaged for distribution and sale.

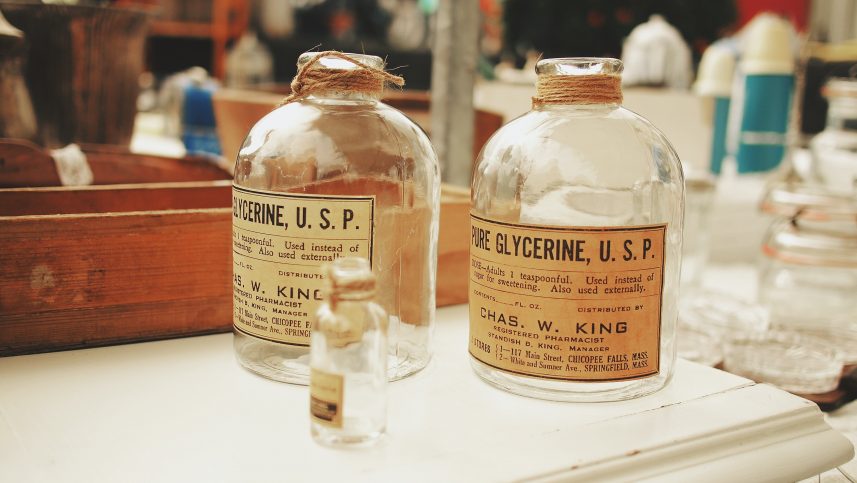

The refined glycerine produced in these refineries can be used in various applications, including cosmetics, pharmaceuticals, food and beverage additives, and industrial applications. Additionally, glycerine has become a valuable component in the production of biofuels and as a substitute for petroleum-derived products.

Glycerine refineries play a crucial role in the efficient utilization of glycerol by converting it into a valuable and versatile product with a wide range of applications in different industries.

TECHNOILOGY glycerine Refining process can guarantee pharmaceutical grade products matching all international standards. Glycerine Treatment Concentration and Distillation units are capable of processing all kind of crude glycerine coming from sweet water, spent lye and biodiesel.